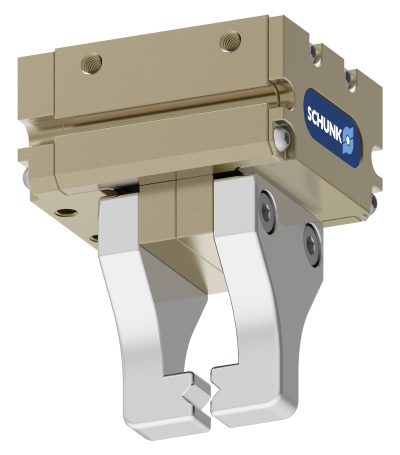

Pnuematic Gripper

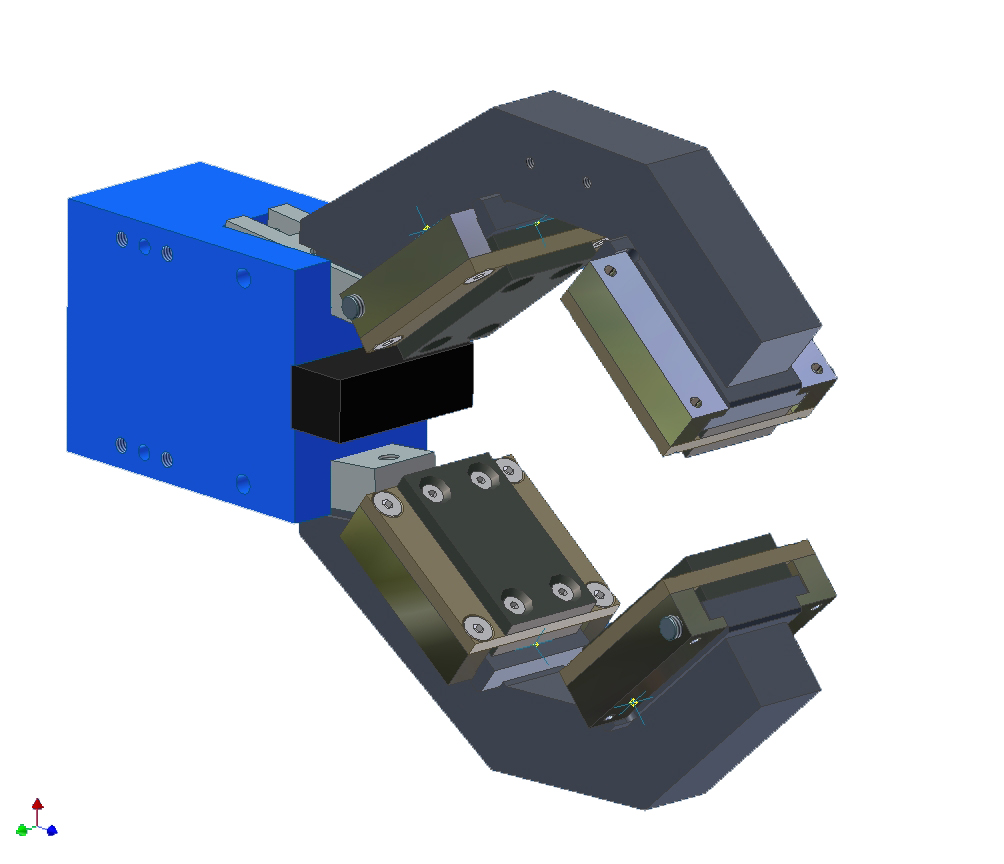

The three major types of pneumatic grippers are parallel gripper angular gripper design and custom units such as o ring assembly machines.

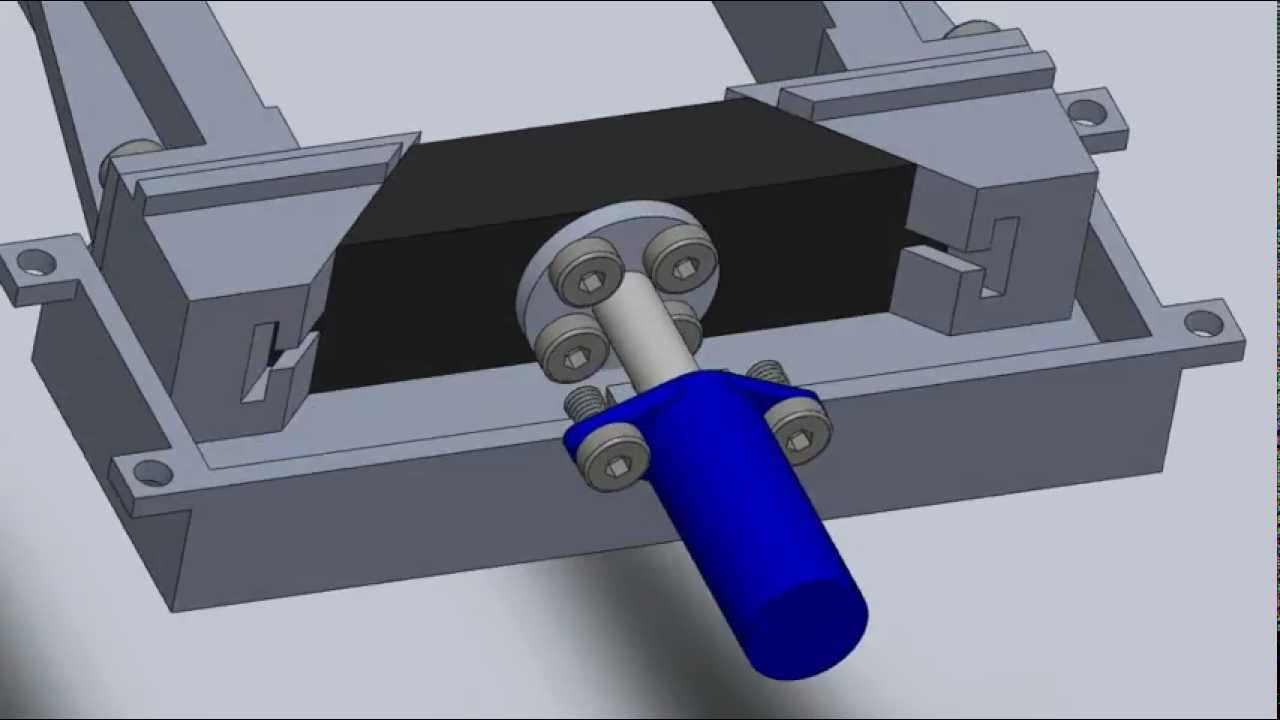

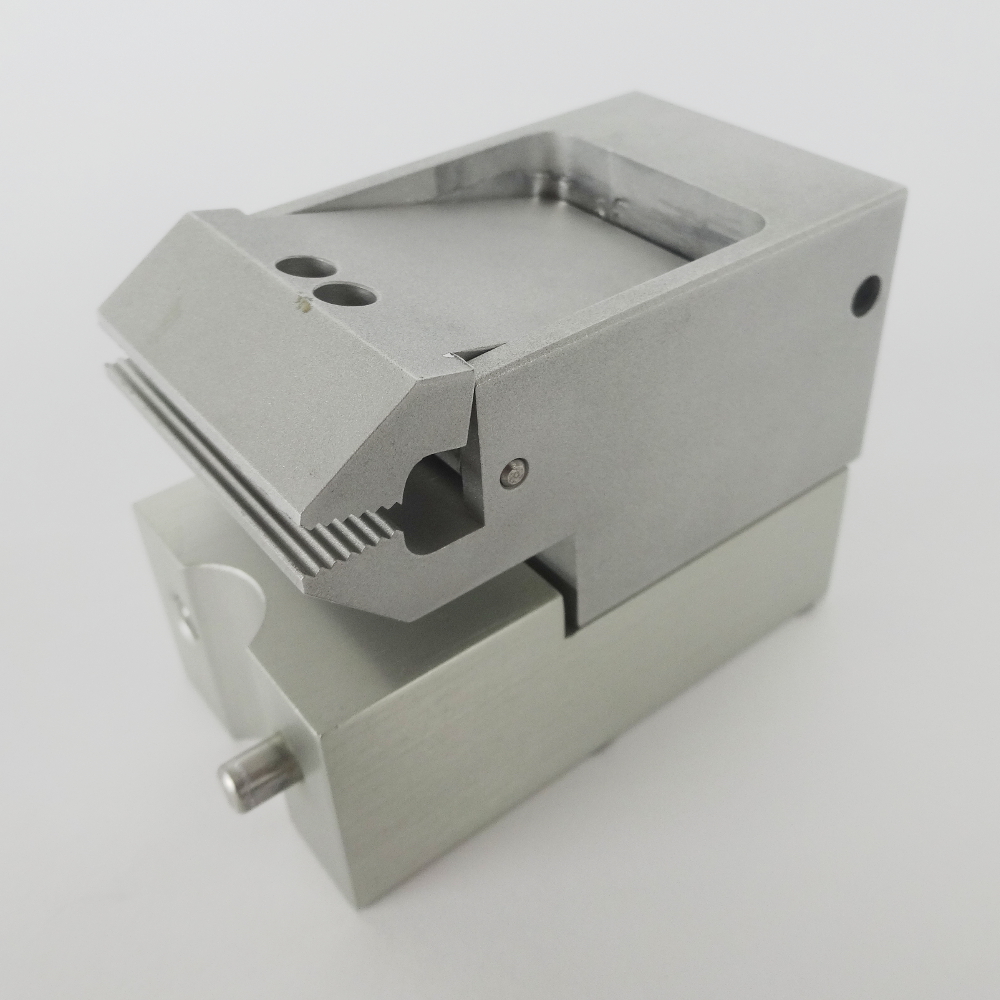

Pnuematic gripper. Grippers are run on compressed air and have the ability to pick up place hold and release objects while an action is being executed. An internal spring opens the jaws to release the grip. A linear guide air gripper utilizes parallel motion to handle objects with two opposing flat surfaces. The jaws grip items from the outside as well as the inside.

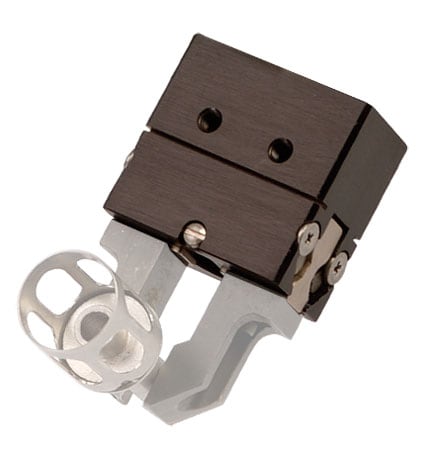

Grippers pneumatic electric angular parallel a wide variety of phd pneumatic grippers are available for internal and external gripping uses and have various jaw styles to adapt to any application. One to move the jaws open and another to move them closed. Grippers with a spring jaw return have a single air port to close the jaws and grip items from the outside. Grippers with a forced air jaw return have two air ports.

Reliable pneumatic grippers from grainger can help an automated system or industrial robot pick up and move components in a manufacturing operation. These products are used in various industries such as aerospace automotive appliance automated industrial o ring systems electronic medical and packaging.